Home | Contact Us | 中文 | English

Home | Contact Us | 中文 | English

The conductive material contains conductive plastic and conductive rubber. Conductive rubber is silver-plated, silver-plated silver, silver and other conductive particles evenly distributed in the silicone rubber, through the pressure of conductive particles contact, to achieve a good conductive effect.

Principle

There is a large number of charged objects in the electric field can be free to move the charged particles, which can well conduct current material. Including conductor materials and superconducting materials. In the field of electrical engineering, conductive materials usually refer to the resistivity of (1.5 ~ 10) × 10-8 ohm metal.

Its main function is to transmit electrical and electrical signals, in addition, widely used in electromagnetic shielding, manufacturing electrodes, electric materials, equipment, etc. (when there is electromagnetic shielding and safe grounding requirements). With the development of science and technology, its use is still increasing.

Characteristics

Electrical materials used in the field should have high conductivity, good mechanical properties, processing performance, resistance to atmospheric corrosion, high chemical stability, but also should be rich in resources, low prices.

Aluminum-plated silver conductive rubber: excellent shielding performance and anti-smoke performance;

Nickel-coated graphite conductive rubber: with excellent conductivity and electromagnetic shielding, corrosion resistance

Copper-plated silver conductive rubber: with the best conductivity;

Glass silver plated conductive rubber: with the best price / performance ratio;

Silver conductive rubber: has a good anti-fungal.

Classification

Common materials

Commonly used metal conductive materials can be divided into: metal elements, alloys (copper alloy, aluminum alloy, etc.), composite metal and not to conductive as the main function of other special purpose conductive materials 4 categories:

(Ag), copper (Cu), gold (Au), aluminum (Al), sodium (Na), molybdenum (Mo), tungsten (W), zinc (Zn) ), Nickel (Ni), iron (Fe), platinum (Pt), tin (Sn), lead (Pb), and the like.

Alloy, copper alloy: silver copper, cadmium copper, chrome copper, beryllium copper, zirconium and copper; aluminum: aluminum and magnesium, aluminum magnesium, aluminum magnesium, aluminum zirconium and so on.

③ composite metal, can be obtained by three kinds of processing methods: the use of plastic processing for composite; the use of thermal diffusion composite; the use of coating for composite. High mechanical strength of the composite metal are: aluminum clad steel, steel and aluminum tram lines, copper clad steel, etc .; high conductivity composite metal: copper clad aluminum, silver and aluminum; high elastic composite metal: copper complex beryllium, spring copper Copper-clad copper, nickel-coated silver, etc .; corrosion-resistant composite metal are: stainless steel copper, silver copper, tin-plated copper, silver-plated copper package Steel and so on.

④ special function Conductive material is not conductive as the main function, and in the electric, electromagnetic, electro-optical, electrochemical effects have good performance of the conductor material. They are widely used in electrical instrumentation, thermal instrumentation, electrical, electronic and automation devices in the technical field. Such as high resistance alloy, electrical contact materials, electric materials, temperature control thermoelectric materials. Important are silver, cadmium, tungsten, platinum, palladium and other elements of the alloy, iron chromium aluminum alloy, silicon carbide, graphite and other materials.

Main performance: The electrical properties of conductive materials are mainly characterized by resistivity. Factors affecting the resistivity of the temperature, impurity content, cold deformation, heat treatment. The effect of temperature is often expressed as the temperature coefficient of the resistivity of the conductive material. In addition to near melting point and ultra-low temperature, in the general temperature range, the resistivity with a linear change in temperature, can be expressed as

Ρ = ρ0 [1 + α (t-t0)] where ρ is the resistivity at temperature t, ρ0 is the resistivity at temperature t0, t0 is usually 0 ° C or 20 ° C, and α is the temperature coefficient of resistivity. Such as pure metal α of 10-3 to 10-4 ° C -1, alloy conductor α is 10-4 to 10-5 ° C -1. The effects of alloys and impurities are manifested as impurity and alloying elements that cause the metal lattice to be distorted, resulting in an increase in the probability of electron scattering and hence an increase in resistivity.

So high resistance conductive materials are composed of alloy. The effect of cold deformation is often expressed as the stress coefficient of resistivity. In the case of elastic compression or stretching, the metal resistivity varies according to the following formula: ρ = ρ0 (1 + Kσ) where σ is the stress and K is the stress coefficient.

Compression is K is negative, ρ decreases, tensile K is positive, ρ increase, so the conductor after stretching resistivity increases. The effect of heat treatment is that the conductive metal is cold-drawn, the strength and hardness increase, the conductivity and plasticity decrease. After annealing, the grains are restored, recrystallized, the grain defects are reduced, the lattice distortion is reduced, the internal stress is removed, and the resistivity decreases.

Composites

Composite polymer conductive material, by the common polymer materials and a variety of conductive substances through the filling compound, surface composite or laminated composite system and other ways. The main varieties are conductive plastic, conductive rubber, conductive fiber fabrics, conductive coatings, conductive adhesives and transparent conductive film.

Its performance and the type of conductive filler, dosage, size and status and their dispersion in the polymer material has a great relationship. Commonly used conductive filler is nickel-coated graphite powder, nickel-coated carbon fiber carbon black, metal powder, metal foil, metal fiber, carbon fiber and so on.

Structural materials

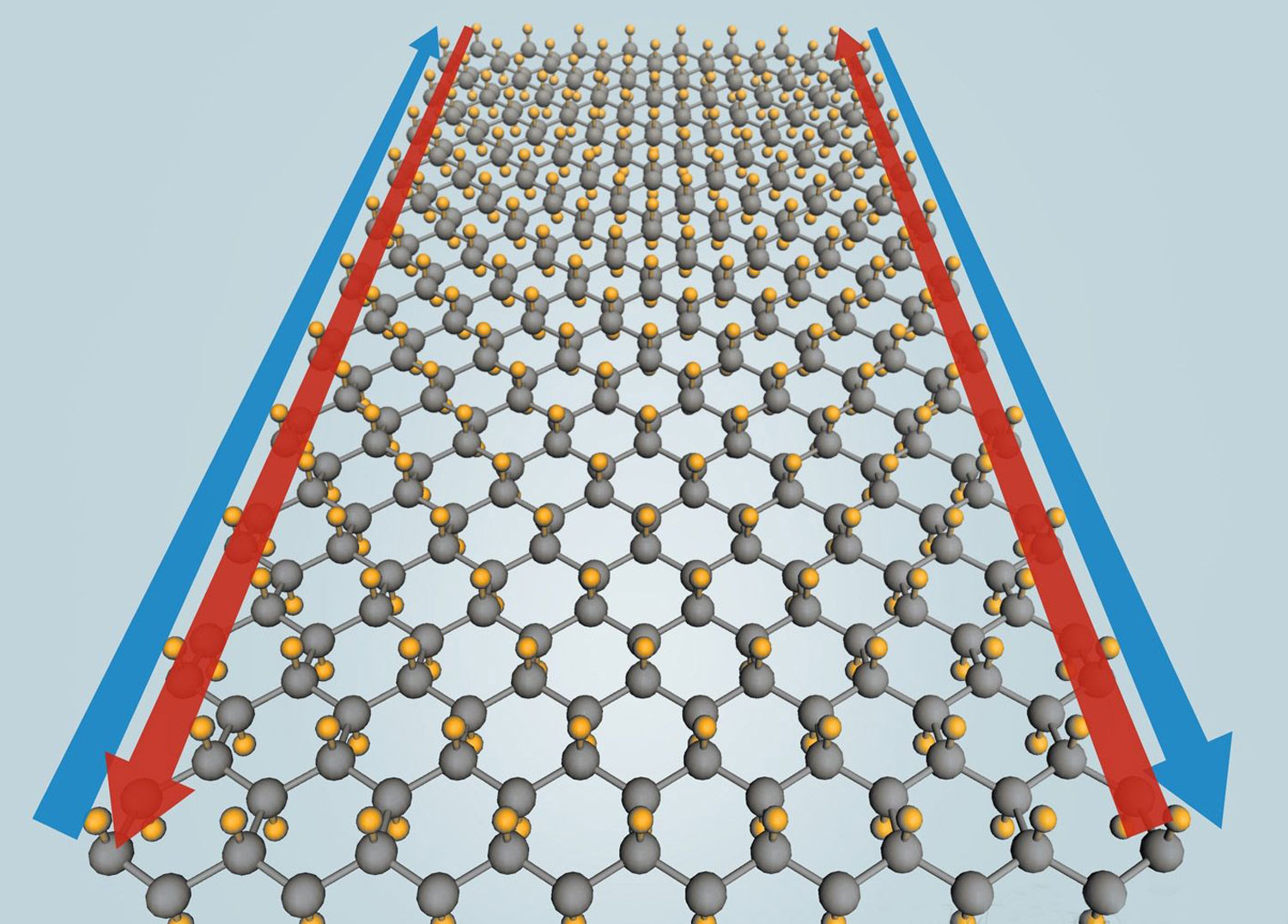

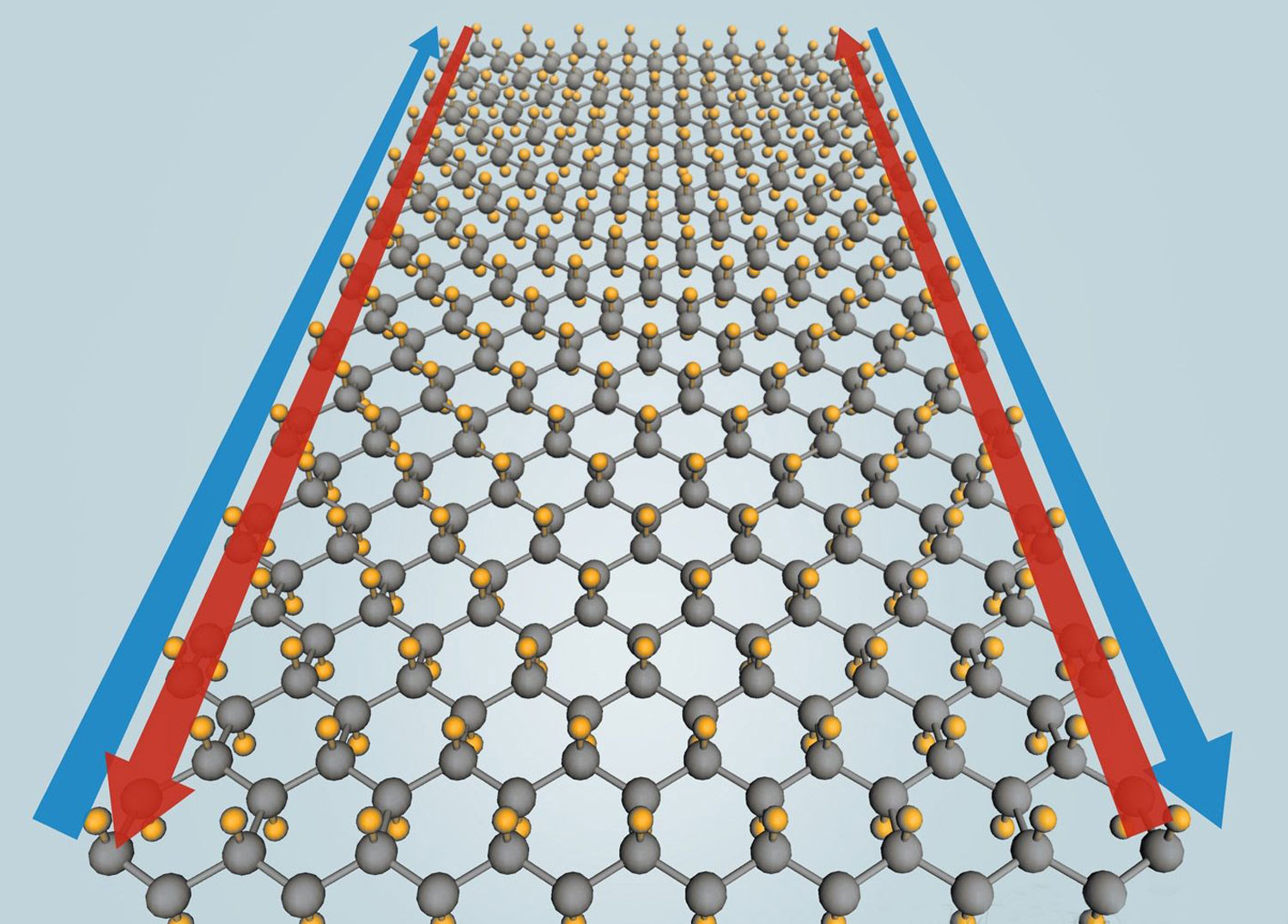

Structure-type polymer conductive material, refers to the polymer structure itself or after doping with conductive function of the polymer material. According to the size of the conductivity can be divided into polymer semiconductors, polymer metals and polymer superconductors. According to the conductive mechanism can be divided into electronic conductive polymer materials and ion conductive polymer materials. Electronically conductive polymer material is characterized by a linear or faceted large conjugate system, under the action of heat or light through the conjugate π electron activation and conductivity, the conductivity is generally in the semiconductor range. The use of doping technology can greatly improve the conductivity of such materials. Such as polyacetylene doped with a small amount of iodine, the conductivity can be increased by 12 orders of magnitude, as "polymer metal."

The doped polysulfide can be converted into a polymer superconductor at ultra-low temperature. Structure of polymer conductive materials for the trial of lightweight plastic batteries, solar cells, sensors, microwave absorption materials and trial production of semiconductor components. However, this kind of material has not yet entered the practical stage because of the poor stability (especially the poor oxidation stability of the doped material in the air) and the processability and mechanical properties.

Previous:Conductive graphite product line

Next:No